What is a goods lift?

The goods lift is a machine used to lift the load between floors or to a certain level. It is used in many areas such as warehouses, logistics, factories, shopping centres, construction, especially in industrial sectors. These lifts, which are specially produced on demand, have a load carrying capacity between 100 kg and 10,000 kg. There are two types as scissor lift and column lift.

Standard Specifications

- Our products are CE Certified in accordance with the standards.

- Scissor St-52 material

- Honed Tubing and Chrome plated shafts for Hydraulic Cylinders

- Hose burst valves in case of hydraulic leaks or hose burst to prevent load dropping.

- Lubricated bushings at moving points

- Lubricated ball bearing rollers

- High strength steel construction

- Suitable for pit or floor mounting

- Safety valve against overloads

- Speed regulating valve to adjust the descent speed

- Quality compact hydraulic power unit

- Control, button control or remote control

Hydraulic Goods Lift Types

Freight lift models, also called load platform, are divided into two as scissor and column.

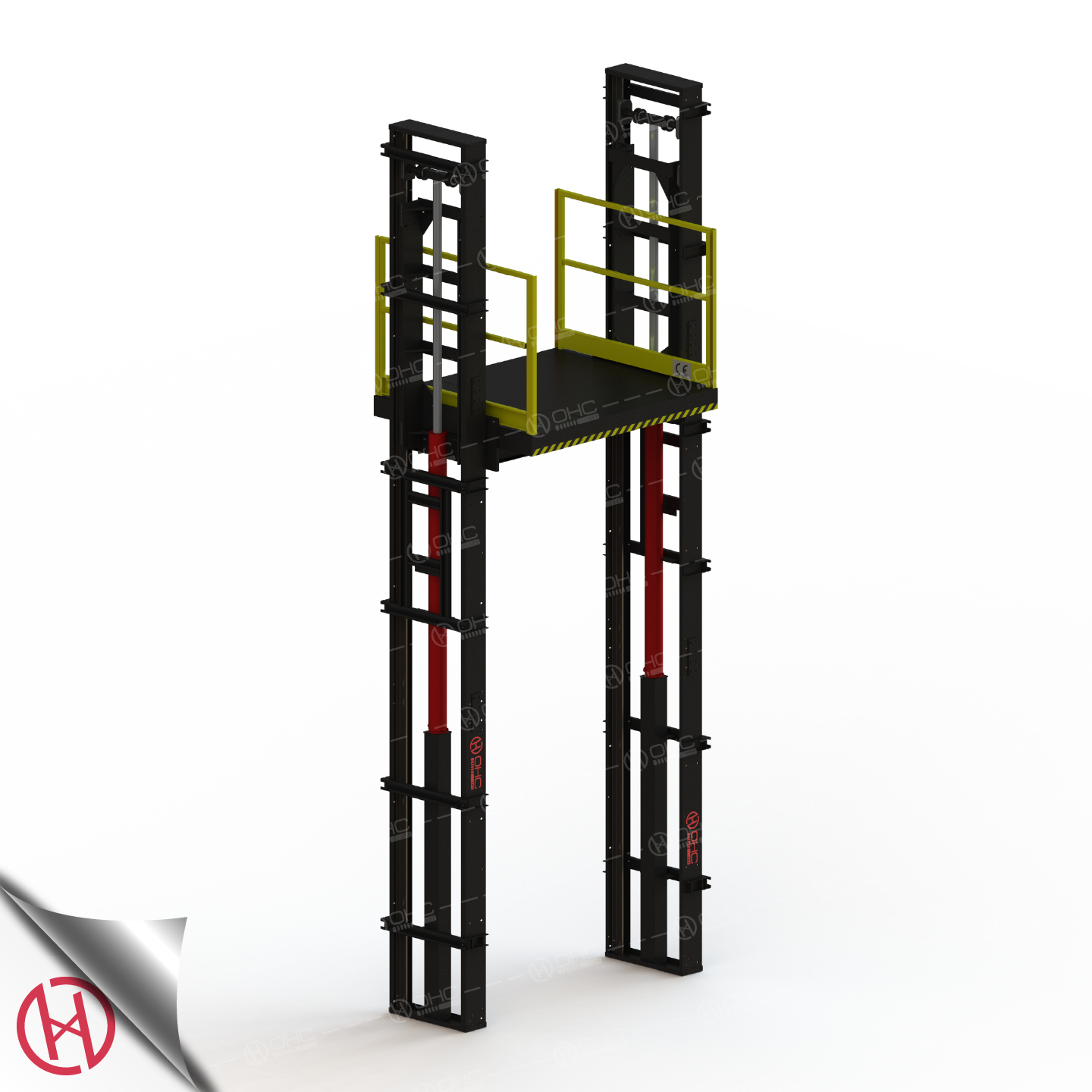

Column Goods Lift

This type has platforms that move on a vertical column. These platforms work with hydraulic and electrical systems to carry weights up and down. Generally used outside the building, this product, also known as construction lift, is used in various sectors such as workplace, facade, industry. Column carriage freight elevator has a travel distance of up to 12 metres. Their advantages over other hydraulic hoists are their compact design, low cost and ease of use.

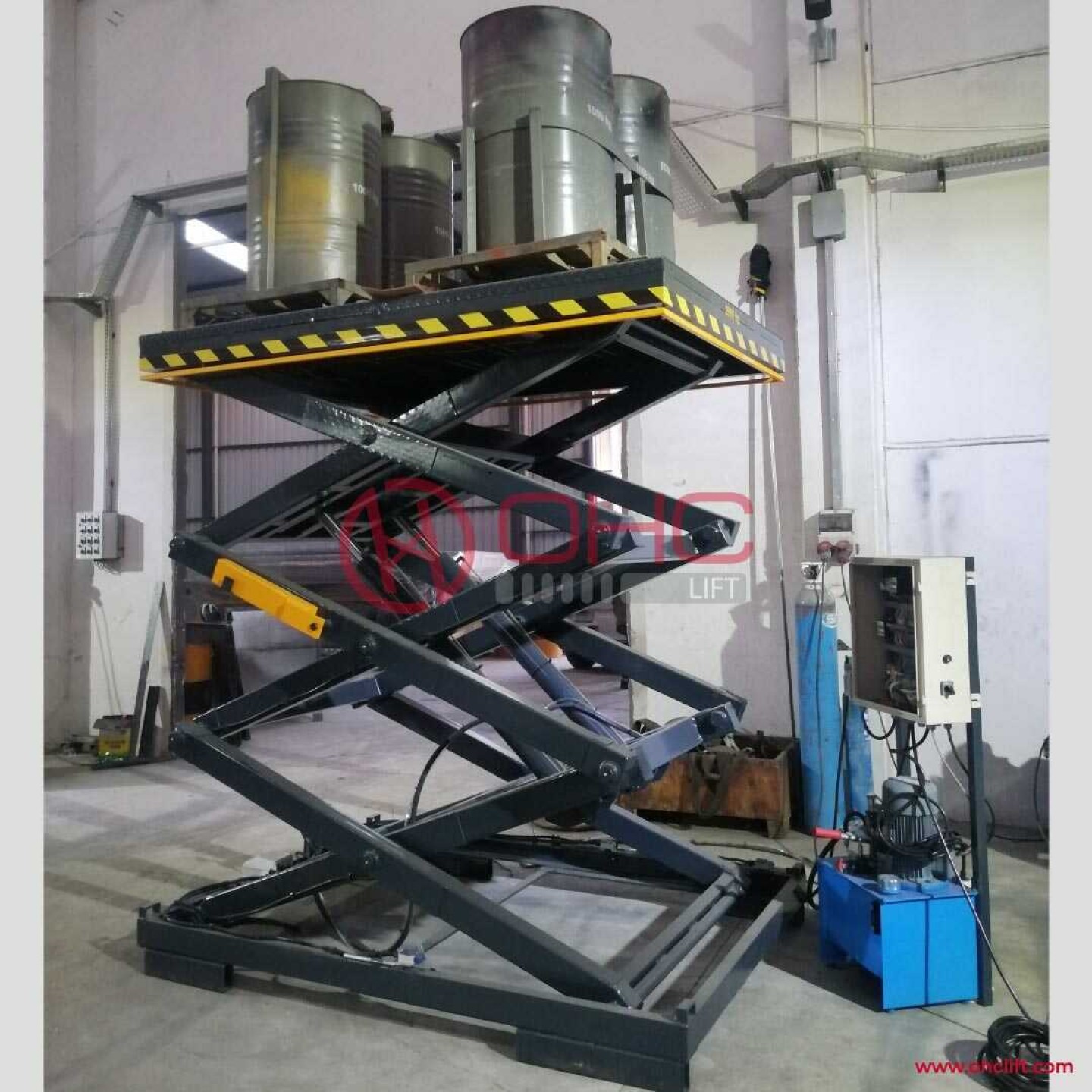

Scissor Cargo Lift

The scissor lift carries the load up and down using one or more scissor mechanisms under the load platform. The number of scissor mechanisms is selected according to the dimensions of the hydraulic goods lift; it works with hydraulic cylinder and electric motor. It is used for transporting materials between floors in warehouses, hospitals, heavy industry, production, logistics and many other areas. It has advantages such as lifting heavy items and durability.

Goods Lift Prices

Goods lift prices are determined according to the type of product and the equipment to be used. Cost calculations are as follows:

- For column lift: Cost calculation will be made considering the number of columns to be used, platform dimensions, travelling distance and weight capacity.

- For scissor lift: The price is determined by the number of scissors to be used, weight lifting capacity, maximum height to be reached and the cost of optional accessories to be used.

Dimensions and Equipment

Hydraulic load carrying lift is produced individually. Its dimensions are generally between 0 and 12 metres and it can have a carrying capacity of 10 tonnes. Floor mounted or pit mounted, after the capacity is known, the dimensions will be determined by making the necessary calculations. For detailed information, you can read our goods lift dimensions article.

Areas of Use

Freight lifts are an important piece of equipment used in various industries for the safe, fast and efficient transport of heavy loads. Below, the most common areas of use are explained in detail:

- Warehouses and Logistics Centres: Industrial freight elevators play a critical role in processes such as the need to move products to the shelves in warehouses and the transport of loads to or from vehicles in logistics centres. These lifts save time and reduce labour costs. Especially scissor lifts offer ease of use in narrow spaces thanks to their compact design.

- Factories and Production Facilities: In factories, goods lift are preferred for transporting heavy machinery, raw materials or other materials used in the production line. These products accelerate the production process and allow operations to continue without interruption. Column platforms offer an effective solution in high-rise production facilities.

- Construction Industry: Column hoists used in construction sites are widely used in transporting construction materials to high floors. Manufactured with materials resistant to harsh weather conditions in construction projects, these lifts are designed in accordance with safety standards.

- Shopping Centres and Commercial Areas: It is used in shopping centres to transport stock products of stores. It also provides an effective solution in the shipment and delivery processes of heavy products in large commercial areas.

- Hospitals: In hospital environments, these systems are preferred for transporting heavy medical equipment and logistics materials. Thanks to their hygienic design and silent operation, they offer solutions suitable for the hospital environment.

- Agriculture and Food Sector: Freight elevators used in the processing and transport of agricultural products are ideal for storing and transporting especially heavy products (grains, fertilisers or machinery). In the food sector, the system is manufactured in accordance with hygiene standards and used in food transport.

Things to Consider When Buying

The type of load, the distance to be transported, the environment where the lift will be used, safety requirements and user needs are the determining factors in the purchase of a freight lift. Here are the main factors to be considered in the selection of hydraulic freight elevators:

- Load Capacity: It can be produced in a wide capacity range. While models with high capacities are preferred for transporting heavy loads in warehouse and production areas, smaller capacity lifts can be used in logistics areas where lighter loads are transported. Cargo lift carrying capacity is between 100 kg and 10,000 kg.

- Travelling Distance: The distance the cargo platform travels between floors determines the type of system to be selected. While scissor lifts provide advantages in workplaces with low travelling distances, column systems are more suitable for high-rise buildings and exterior applications.

- Area of Use: The environment where it will be used affects the design of the system. For example, while more durable materials are used for outdoor applications such as construction sites, safety and aesthetic factors may be at the forefront indoors. In warehouses, compact solutions can be preferred to save space.

- Safety Precautions: Safety is one of the most important factors for industrial freight elevators. OHC Lift offers various safety accessories and systems. These include overload protection systems, emergency stop buttons, anti-slip platforms and safety barriers. In addition, compliance with international standards such as CE certification ensures safe and long-lasting use of the lift.

- Energy Efficiency: Energy efficiency should also be considered when choosing between hydraulic and electric systems. Hydraulic lifting systems generally save energy and require less maintenance. However, the power of the motors used and the overall performance of the system directly affect operating costs.

Hydraulic Cargo Lift Company

OHC Lift, which is one of the goods lift companies, makes demand-specific production in Izmir, Istanbul, Ankara and dozens of cities where the industry is intense. Please contact us to get a price quote from our company which manufactures in CE standards and certified.

Column Goods Lift Technical Specification

Column Goods Lift Technical Specification- Cruising distance 0 – 12.000 mm

- Capacity 100 – 10.000 kg

- Dimensions vary according to the load it will carry and the area to be installed.

Scissor Lift Table Technical Specification

Scissor Lift Table Technical Specification- Cruising distance 0 – 12.000 mm

- Capacity 100 – 10.000 kg

- Dimensions vary according to the load it will carry and the area to be installed.