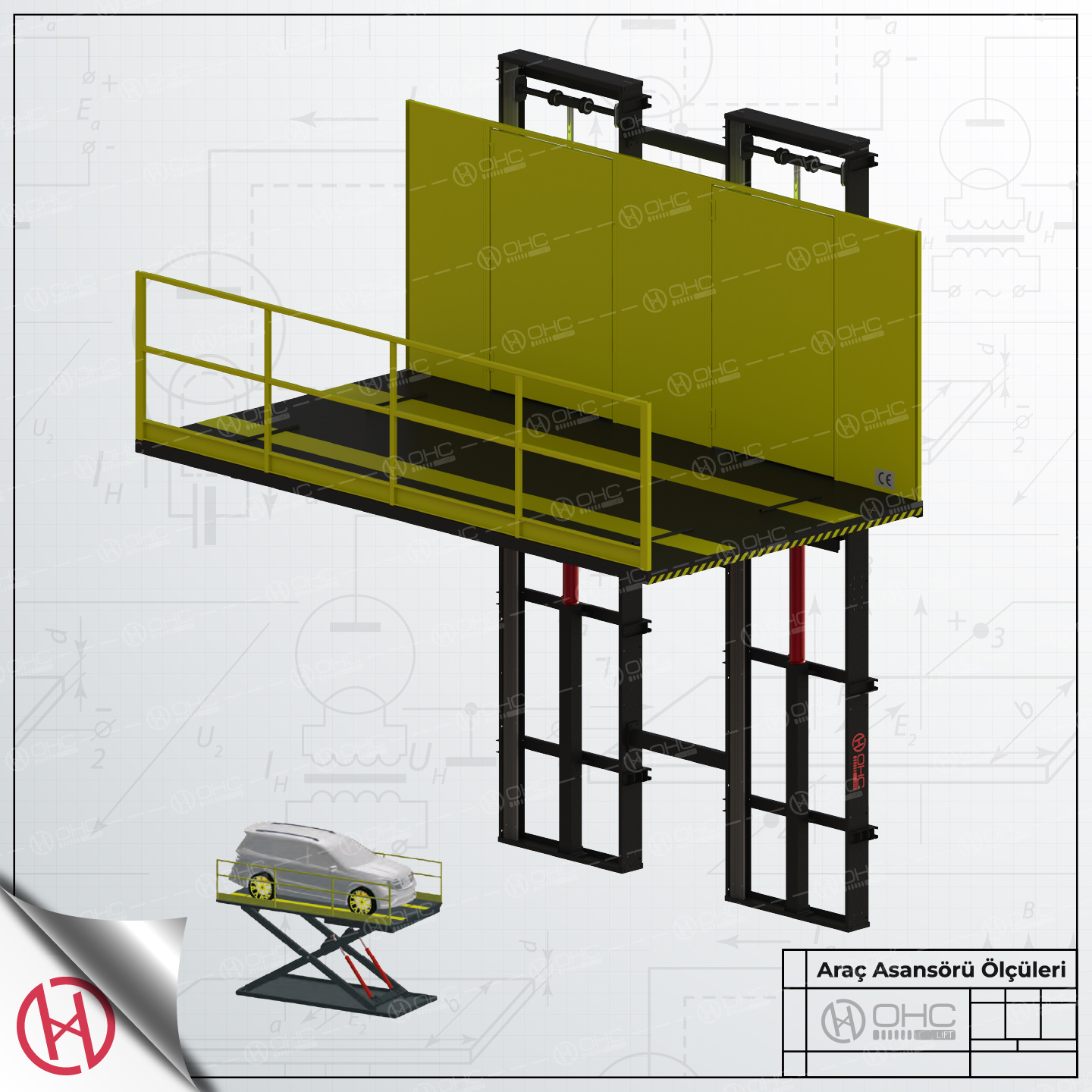

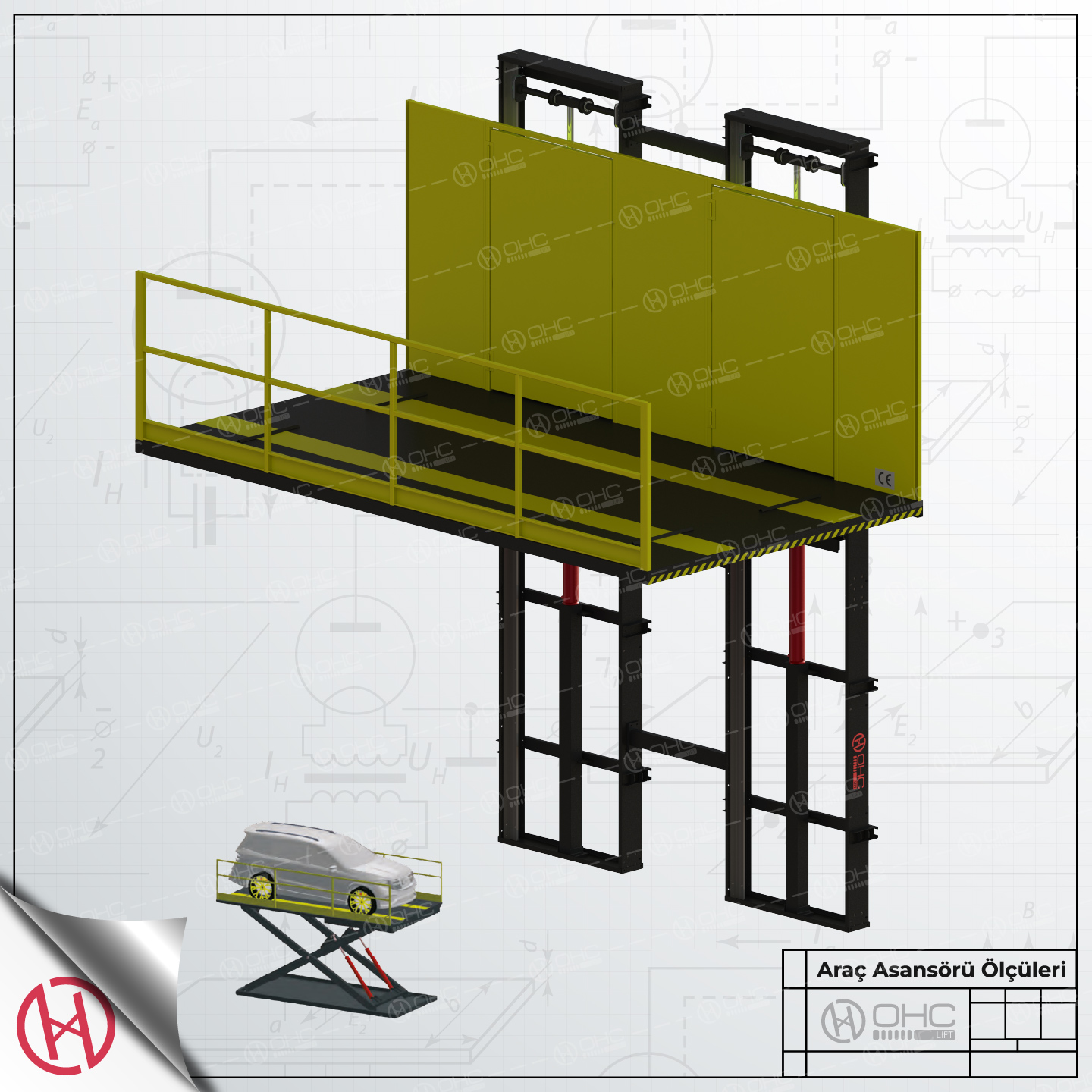

Vehicle elevators are essential hydraulic systems, especially in parking lots, commercial buildings, and industrial facilities. Determining the correct measurements plays a critical role in successfully integrating these systems. So, what dimensions should be considered in vehicle elevator design? In this article, you will find everything you need to know about vehicle elevator dimensions.

Why Are Vehicle Elevator Dimensions Important?

The dimensions of a vehicle elevator are important both functionally and aesthetically. The correct dimensions ensure that the elevator:

- Is suitable for different types of vehicles,

- Meets safety standards,

- Provides energy efficiency,

- Is compatible with architectural design.

For this reason, a custom design approach should be adopted for each project.

Standard Vehicle Elevator Dimensions

Vehicle elevators can be designed in various sizes. However, the following standards are generally used:

1. Cabin Dimensions

Width: 250 cm - 350 cm

Length: 500 cm - 700 cm

Height: 200 cm - 250 cm

2. Load Capacity

It can range between 2,000 kg and 5,000 kg.

The required capacity is determined based on the weight of the vehicles to be transported.

3. Door Dimensions

Width: 250 cm - 300 cm

Height: 200 cm - 220 cm

4. Shaft Dimensions

Width: 300 cm - 400 cm

Depth: 600 cm - 800 cm

Height: Minimum 350 cm

Project-Based Customization

In some projects, standard dimensions may not be sufficient. Special solutions are required in the following cases:

- High Load Capacity: Designs with capacities up to 10,000 kg can be made for heavy commercial vehicles.

- Low-Ceiling Usage: Ceiling height can be optimized for buildings with low ceilings.

- Curved Areas: Designs that provide easy maneuverability are preferred in narrow spaces.

Key Considerations in Vehicle Elevator Design

- Compliance with Safety Standards: Meeting international standards such as CE and ISO certifications.

- Energy Efficiency: Minimizing energy consumption in hydraulic systems.

- Ease of Maintenance: Ensuring long-lasting systems that require minimal maintenance.

- Spare Part Availability: Quick spare part supply for potential malfunctions.

Successfully designing a vehicle elevator is possible by properly analyzing the usage area and needs. At OHC Lift, we provide project-specific solutions to ensure maximum efficiency and safety. For more information about our vehicle elevator solutions, feel free to contact us.

Frequently Asked Questions

- How are vehicle elevator prices determined? Prices vary based on load capacity, cabin dimensions, material quality, and customization requirements.

- How long does it take to install a standard vehicle elevator? The installation time varies depending on the scope of the project and generally takes between 4 to 8 weeks.

- What safety measures are included in vehicle elevators? Safety measures include emergency stop buttons, automatic braking systems, and sensor-equipped door mechanisms.